Contents:

“If it ain’t broke, don’t fix it.” The engineer’s motto holds strong for almost every situation — but when are your machines going to break? For years, the manufacturing industry has sought to answer this question with numerous solutions, such as reactive and preventative measures. However, predictive maintenance with machine learning technologies has the greatest potential to net manufacturing companies significant savings on maintenance costs. That’s why it’s time to learn about how to implement these strategies into your business, and this guide is your best place to start.

What is Predictive Maintenance?

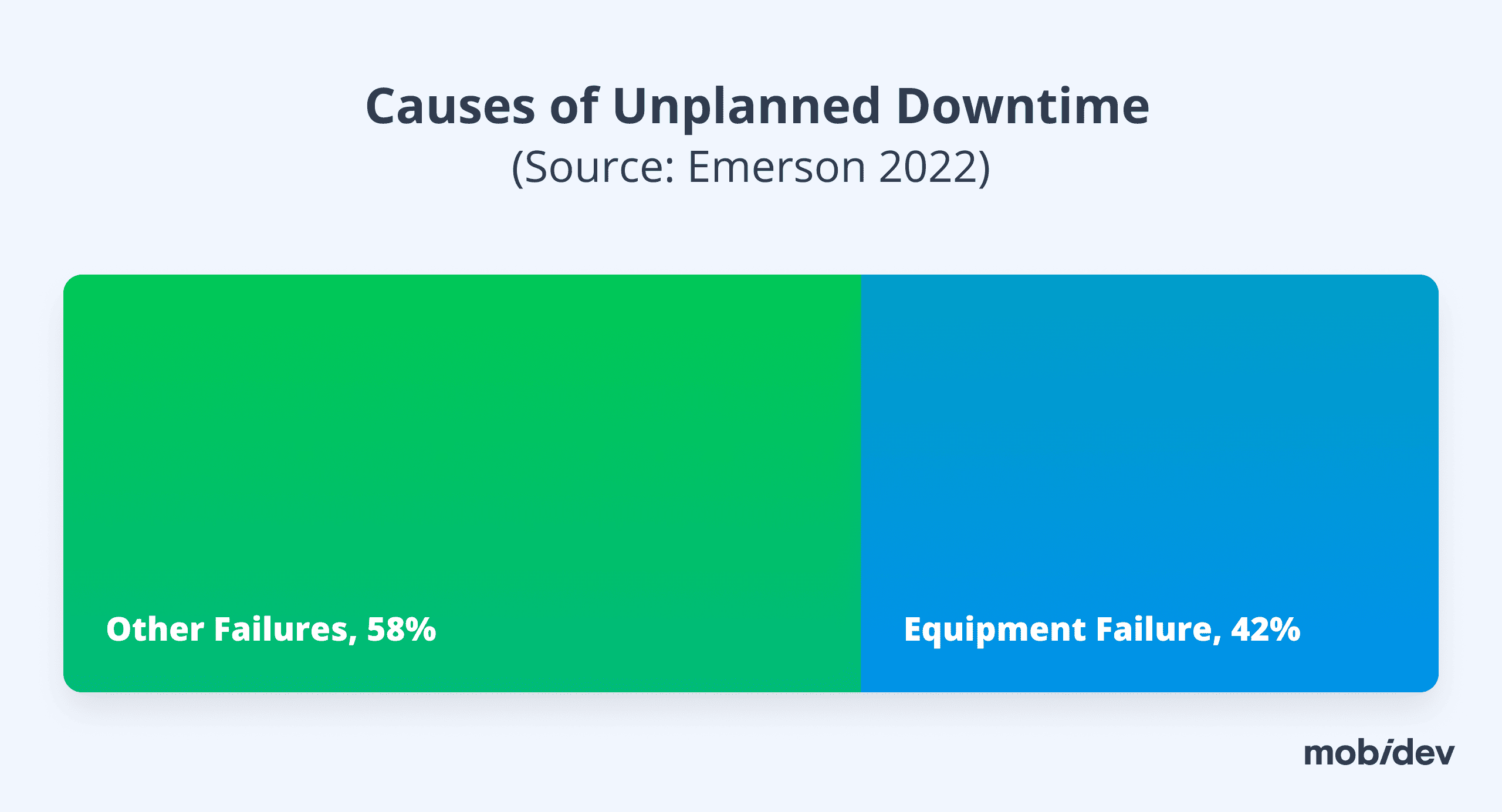

Is unplanned maintenance expensive? Emerson thinks so, at a figure of $50 billion a year, with 42% of that downtime being equipment failure.

Your operations are sitting on a treasure trove of data waiting to be tapped into. By using advanced sensors, you can determine heuristics that may indicate that a machine will soon need repairs. That’s exactly how predictive maintenance using AI works: using data to figure out when you need to replace parts and perform repairs next.

The key premise is using historical data to make predictions about the future. If certain characteristics of a machine, like temperature, pressure, and vibration, increase before the machine fails, you should be able to make assumptions about when the machine will fail again in the future.

Since data is the meat and potatoes of predictive maintenance, machine learning is the perfect tool for the job. With AI models pouring over the data constantly, you can automatically and efficiently get alerts about when machinery needs to be repaired and maximize operation time.

Comparing Reactive, Preventative, and Predictive Maintenance Approaches

Manufacturers have been finding ways to minimize their downtimes and optimize equipment repair for over a century. Let’s compare the benefits of predictive maintenance against preventative and reactive strategies.

Reactive maintenance is the oldest strategy. When something breaks, you fix it. This is the most expensive approach and the one we want to avoid. This is especially the case if the part you need has to be imported from abroad and incurs steep, unplanned shipping costs.

Preventative maintenance is done at set intervals. For example, your car’s manufacturer recommends that you change your brake fluid every several years. This can work fine, but all you’re doing is repairing machines at routine intervals. It’s not being done based on the specific characteristics or performance values of the equipment. For example, different usage patterns may accelerate component degradation.

| # | Aspect | Reactive Maintenance | Preventative Maintenance | Predictive Maintenance |

|---|---|---|---|---|

| 1 | Objective | Repair equipment when it breaks | Keep the equipment from breaking with routine repairs | Use data to determine when equipment will most likely break |

| 2 | Timing | Unplanned | Routine | Based on real-time conditions & data |

| 3 | Cost | High long-term costs | Moderate | High up-front cost, but lowers long-term costs |

| 4 | Downtime | Highest downtime | Less downtime | Least downtime |

Machine learning for predictive maintenance solves both problems. Like preventative maintenance, predictive approaches find a way to avoid disrupting operations. However, predictive methods are better, because they are attentive to the status of the equipment. If a machine learning model is trained well enough, changes in a machine’s use, environment, or other factors will be considered automatically when predicting when repairs need to be made next.

Technologies Used in Predictive Maintenance

If we’re going to be anticipating equipment failures, we should familiarize ourselves with all the technologies that make predictive maintenance using AI possible. To list just a few of the most common:

- Internet of Things (IoT): looking to collect real-time data from your equipment? You’ll need lots of small, fast, edge computing devices that can report home about heat, vibration, pressure, and other heuristics.

- Artificial Intelligence: Your IoT devices collect the data, and AI understands it. Machine learning is one of the most popular domains of AI that can be used to analyze patterns in the data to predict when equipment will fail.

- Data Analytics: this is the scientific domain that encompasses dealing with the large datasets with which you’ll be confronted. Data analytics tools and strategies are fundamental to AI for predictive maintenance in manufacturing.

- Cloud Computing: for high availability and scalability, you might consider processing all that data in the cloud.

- Predictive Modeling: statistical analysis helps you figure out when machines will fail based on collected data.

- Digital Twins: lets you simulate performance changes and predict your maintenance needs based on different conditions.

Use Cases for AI in Manufacturing and Maintenance

Predictive maintenance these days is primarily driven by AI, another technology that has a lot of other applications in manufacturing. So, let’s look at some AI use cases in manufacturing and see how predictive maintenance fits into the bigger picture.

Total Productive Maintenance (TPM)

For most businesses, technicians are responsible for equipment maintenance — but what if everyone played a role in caring for your machines? That’s hard to accomplish without AI and predictive maintenance.

By monitoring equipment extensively using an array of sensors, predictive maintenance systems can send notifications to workers’ devices to give them instructions on how to perform maintenance operations. Certain tasks can also be grouped by skill level or certification. This ensures that workers aren’t asked to perform corrections on equipment without appropriate training and experience.

Improved Overall Equipment Effectiveness (OEE)

AI in predictive maintenance can help beyond individual machines if we look at the bigger picture.

Let’s imagine that your factory has two stages. The first stage moves components through at twenty units per hour, passing units off to the second stage. However, the second stage can only manage ten per hour. As a result, the factory is less efficient.

In many cases, this situation may not be as obvious. AI excels at detecting inefficiencies like this. OEE can help plant leadership make important decisions, like installing a second machine to enhance the second stage of our hypothetical factory. Here’s how OEE is calculated:

OEE=Availability × Performance × Quality

Predictive maintenance plays a key role in OEE; it reduces downtime, increases productivity, and cuts down on costs. These benefits help with each of the three components of the OEE calculation.

Optimal Maintenance Scheduling

So, we’ve explored how predictive maintenance can tell us when machines need to be serviced. However, as any good plant leader or manufacturing executive knows, it’s not that simple. There are other factors that can affect when maintenance can be performed. Production, supplier, and vendor schedules, parts availability, and other operational constraints can all get in the way of getting things done immediately. There’s a lot to keep track of, but this is just the kind of challenge AI is built to conquer.

Once predictive maintenance programs have identified when equipment needs to be serviced, other AI systems can get to work figuring out the optimal time to schedule that maintenance. This requires the AI systems to have access to your plant schedule and other information about those challenges mentioned earlier. The more information it has access to, the better it will be at finding a cost-effective time to set aside to get machines fixed.

Machine Learning Algorithms Used in Predictive Maintenance

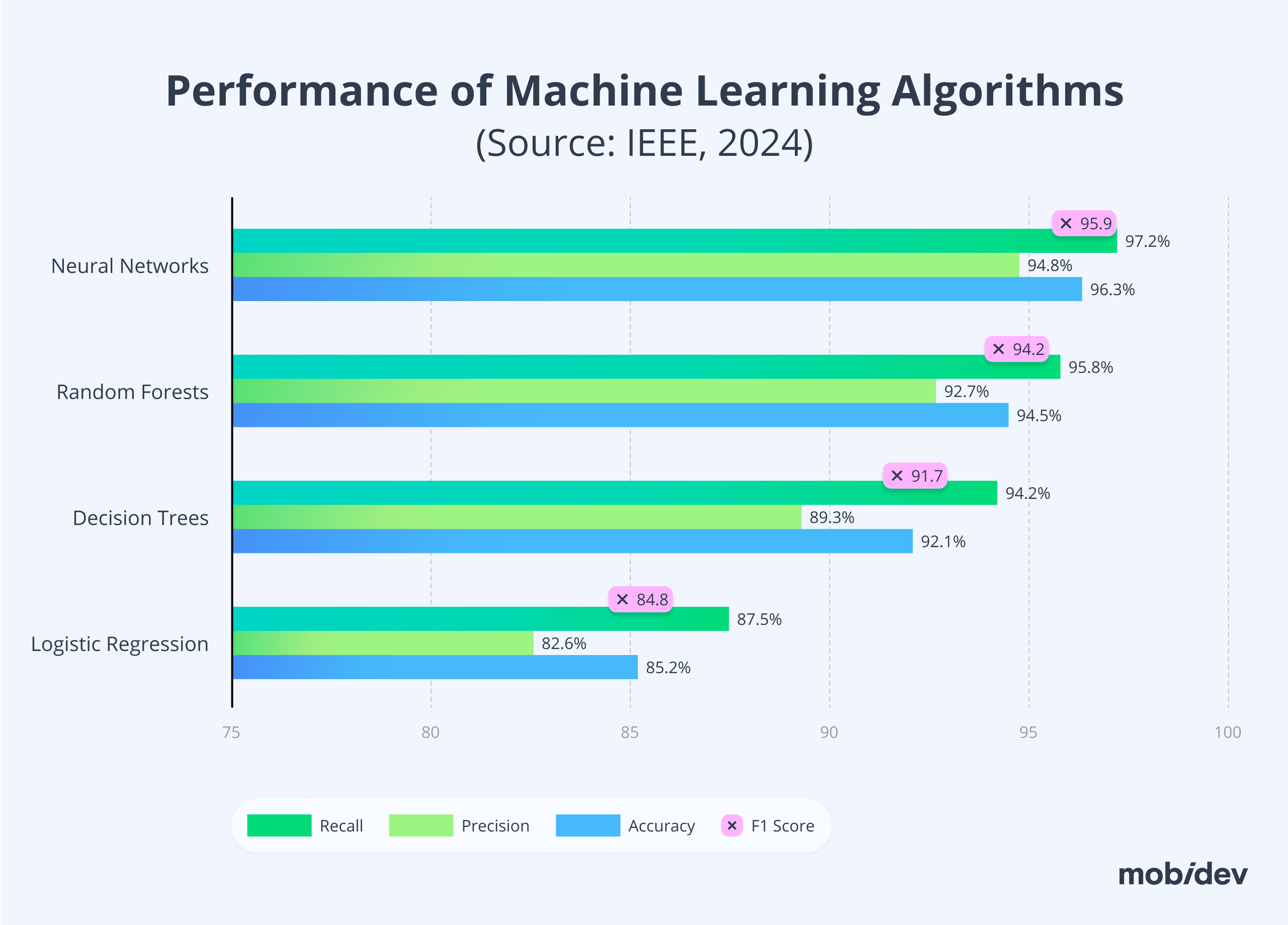

There’s no single approach to machine learning for predictive maintenance. We’d be here for a while if we covered every algorithm out there, so let’s focus on four big ones: neural networks, random forests, decision trees, and logistic regression. These are each supervised learning model, where the data is labeled and monitored by data scientists.

According to a study by researchers published in the 2024 2nd International Conference on Networking, Embedded and Wireless Systems (ICNEWS), neural networks outperform random forests, decision trees, and logistic regression algorithms in predictive maintenance applications. They assigned neural networks an F1 score of 95.9, having superior recall, precision, and accuracy compared to the other three models.

However, it’s important to keep in mind that, although neural networks are powerful, they have greater resource demands. The computational power and training time needed for them to perform predictive maintenance effectively can be greater than alternative methods. However, in the long run, the performance of neural networks can potentially pay for itself.

Since neural networks are also black boxes, it can be difficult to understand why the system makes the decisions that it does. As a result, other algorithms may be better choices. You can also combine algorithms together with ensemble learning to enhance their overall performance.

Unsupervised Learning

Instead of using labeled data and output labels (called responses), unsupervised learning uses data without labels. A few methods in this category are Gaussian mixture models and K-means clustering. These methods are best used for identifying outliers as they occur without previous training or historical data. Once anomalies are detected, plant staff can be informed automatically to investigate further.

Since production lines are very different, we can’t say that some algorithm is the best solution. Each case requires an individual approach. Involving experienced machine learning engineers can help you choose the best option for your production and reduce the risks of unnecessary investments.

Machine learning consulting services

Discover moreHow to Implement Predictive Maintenance: Challenges & Best Practices

So, what’s stopping you from putting a crystal ball in your plant? Well, nobody said it would be easy — but it’s certainly worth it. The best place to start is to strategize. Identify all the challenges that you might face when implementing predictive maintenance using machine learning. Then, make sure that your strategy addresses each of these obstacles. Data science experts and AI development teams have the experience needed to help you figure out the answers that align best with your production line and your budgetary needs.

Entry Cost

The sticker price on artificial intelligence in maintenance for manufacturing can be a tall order. Getting budgetary approval for an investment like that can be a headache. More importantly, figuring out a way to integrate new sensors with your established machinery and equipment can incur more costs. However, in the long term, predictive maintenance’s potential to reduce downtimes and repair costs can more than make up for the cost of your initial investment.

Data Needs

Predictive maintenance systems are AI-driven and are hungry for data. So, where are you going to get all the data from? Where are you going to store it? How are you going to transmit data from sensors to the computers that are going to process it? Those are all questions you’ll have to answer when implementing predictive solutions for your business.

Data Quality

Will the sensors you attach to your equipment always be accurate? If they aren’t maintained, they may produce inaccurate data that can have consequences on predictive maintenance insights. You’ll need to come up with a plan to ensure that the data quality is as high as possible to maximize the effectiveness of your system.

Adopt Machine Learning for Predictive Maintenance with MobiDev

Predictive maintenance using machine learning is a lynchpin of modern manufacturing in the AI age. We know that because we’ve worked with the very businesses that are using it. Since 2009, MobiDev has helped businesses —including those in manufacturing — succeed with their software development needs.

Our teams aren’t just experienced in the AI side of things; we have experience with IoT networks and AR/VR applications too. Our in-house AI labs research and develop complex AI solutions for unique problems, and we’d be delighted to help you solve yours.

Talk to us today to find out how our AI consulting and engineering services can help you achieve your strategic goals.