Contents:

Industries explore different ways of using Artificial Intelligence in manufacturing, from calculating adequate fuel consumption to testing virtual copies of machinery in the metaverse. Moreover, AI is expected to make complex high-tech solutions cheaper and more approachable for businesses of all sizes.

Since 2009, MobiDev has specialized in software product development and focused on AI since 2018, so we understand how AI can deliver real business results. In this article, we will review how different branches of the manufacturing industry can use Artificial Intelligence (AI) today and what advancements we may expect in the future.

The Overview of Artificial Intelligence in the Manufacturing Industry

Since the first AI applications in manufacturing proved successful, the volume of investment in this domain has surged. The market for industrial AI is estimated to grow by 46% every year between 2023 and 2028.

Growing interest in AI forces businesses to seek new, cheaper ways to train AI models. Standard AI models are taught bottom-up reasoning, meaning they make decisions based on vast training data. These models, though, cannot generalize in unpredicted situations, like recognizing kids dressed for Halloween. The applications of such algorithms in industrial robotics presuppose a lot of time and training spent on every specific task.

This pushed companies like Samsung and tech leaders like Jeff Bezos and Mark Zuckerberg to seek new ways to train AI. For example, Bezos and Zuckerberg have invested in Vicarious, a start-up that promises to build general-purpose robots that can learn from a few examples. Their prototypes are promising.

In the illustration below, you can see a robot that takes tiny objects, like pieces of lip balm, from a messy heap and neatly packs them in boxes on a conveyor belt.

It is clear that with increased research funding, the number and variety of examples of how to use Artificial Intelligence in manufacturing in a more effective way will grow.

How AI is Used in Manufacturing: 9 Fields of Applications

Let’s dive into the key tasks that AI can solve for the manufacturing industry to see what business value AI implementation can bring to production.

1. Artificial Intelligence for Quality Control

Traditional quality control in manufacturing is usually based on detecting anomalies at various stages of production. AI can improve this process by disclosing surface defects when the human eye skips over them. Computer vision tools powered with deep learning, like Google’s Visual Inspection AI, analyze high-resolution images (100 million pixels), alarm at all the defects presented on them, classify defect types, and trigger follow-up action down the production line. Such automated quality control ensures more effective defect detection and enables predictive maintenance.

2. Predictive Maintenance

Manufacturing equipment must work in challenging environments (like crude oil pumps), through rigid operation schedules, and with dangerous chemical elements. Therefore, preventive and reactive maintenance costs in manufacturing have always been high.

Machine learning predictive maintenance solutions use historical data and real-time telemetry collected by smart sensors to predict the type of mechanical issue before issues become critical. This allows for substituting huge repairs with minor interventions and, thus, saving on costs and increasing equipment uptime.

3. Supply Chain Optimization

During economic or political upheaval, companies should be able to quickly ramp down operations and, similarly, quickly ramp them up if demand recovers. By establishing integrations with systems that affect the supply chain, companies can receive real-time data for more informed decisions. For example, industrial artificial intelligence can operate on real-time data from customers, distributors, factories, suppliers, and retailers.

4. Production Planning

In production planning, AI is used to develop production plans based on available resources, such as equipment and materials. It also can analyze supplier profiles, prices, availability and give recommendations on new suppliers, or review contracts with existing suppliers, pre-screen, summarize them, and detect clauses of interest. It can also automatically feed the insights into ERP for better visibility.

5. Energy Management

Effective energy management is another example of how to use AI in manufacturing. For example, AI can provide automated demand response strategies by predicting peak load periods and optimizing energy allocation accordingly.

6. Customization and Flexibility

Industry moves towards creating unique value for every customer, or toward producing a large variety of “market-of-one” products. This is possible thanks to developing reconfigurable manufacturing systems, allowing for the creation of products of specific design when they are needed.

For example, BMW uses AI technology to generate some design ideas based on preset parameters. As revealed by BMW’s head of design, Adrian van Hooydonk, the company has been experimenting with AI to design car parts, including wheel design.

7. Risk Management

The increasing adoption of Industry 4.0 technologies in manufacturing, such as industrial IoT devices, poses new challenges in industrial risk management, as key parts of production now have to be protected from cyber risk. AI steps in, allowing for heightened security measures, identifying potential risks in operations, predicting supply chain disruptions, and ensuring proactive risk mitigation.

8. Research and Development

AI enhances the research and development stage in manufacturing in multiple ways, from assisting engineers in their daily routines (e.g. GitHub Copilot) to analyzing hypothetical product performance in simulations. AI models are thousands of times faster than the usual physical simulations, so users can test a considerably larger number of potential designs. McKinsey brings an example of a CPG company making material selections by 70x with AI.

9. Employee Training

Detecting the personal skills gaps for every employee is time-consuming and difficult. Yet, making all the staff go through a unified training program is unproductive as well. AI solves this challenge by providing personalized pinpoint testing and training programs, teaching staff only the necessary skills.

TOP 7 Industrial AI Use Cases

Now let’s take a closer look at some interesting cases of AI being used in manufacturing.

1. AI Inventory Management & Supply Chain Optimization

Benefits:

- More accurate production schedules

- Lower risk of overproduction or product shortages

- Proactive decisions

- Cost savings

- Better visibility in inventory

- Real-time updates

Unpredicted delays and financial losses flooded the business world. AI comes to the rescue with its ability to trace dependencies within huge amounts of variables in real-time.

Here’s how it works: A typical AI forecasting solution presented by a group of researchers from leading US universities connects the dots between what drives the demand (prices, promotions, size and behavior of the audience) and what drives the supply (transportation delays, supplier inventories, production constraints). At the output, you receive forecasts on production quantities, inventory stock levels, and shipments between different locations. In case of any changes, the new output is calculated in real time.

For better visibility, this tool builds a digital twin of the whole supply chain network, offering a sneak peek into different demand-and-supply scenarios. So, a business owner can simply test alternative plans, like checking how rerouting a certain shipment will affect costs.

When used for inventory management, the tool described proved quite effective. An unnamed semiconductor equipment provider in the US typically maintained an inventory fill rate of 77% at the cost of $135 million. AI offered the company two working optimization scenarios: either raise the fill rate to 81% but spend $20 million less or raise it to 85% at the same cost as previously incurred ($135 million).

It is also worth noting that between supply and demand, it’s always harder to make demand predictions, as the nature of what makes people buy or ditch certain products is quite complex.

2. AI Demand Forecasting

Historically, demand forecasting has been based on statistical methods like regression analysis for decades, yet it has always failed due to one reason: the assumption that things driving demand in the past would remain unaltered. Implementation of AI demand forecasting mechanisms allows you to more effectively predict future demands, taking into account not only historical data, but also market trends, seasonability, supply chain data, etc.

At MobiDev, we have been working with demand forecasting since 2018, helping leading US POS software providers to introduce advanced forecasts into their products. For example, SmartTab allows venue owners to receive AI-driven demand forecasting insights leveraging data from POS systems. For our other client, Comcash, the MobiDev team implemented an adaptive selective model that predicts demand for the coming weeks based on user retail sales data for specific products at any point in time.

3. AI Defect Detection with Computer Vision

Benefits:

- Faster defect identification

- Quick defect root-cause detection and analysis

- Time-saving

- Downtime reduction

- Cost saving

- Improved scalability

Video and sensor-based defect detection is not a new technology, yet it was criticized for quality issues in the past.

With the help of neural networks, powerful GPUs, high-resolution cameras and real-time video processing, AI inspection for defect detection can perform previously impossible tasks. Thus, factories benefit from faster turnout and better quality of products.

Besides being faster, the defect detection process is safer for products, as visual inspection doesn’t harm individual products, unlike with some sensor systems.

In most industries, AI-based defect detection is used in multiple domains. For example, 3B-Fiberglass, a supplier of thermoplastic and thermoset fiberglass, usually used in automotive and other industries, had issues with glass fibers breaking at one of the production stages. The AI detection tool they used established that all the breakages had a similar pattern, which allowed them to establish the root cause of the effect.

Yet, it’s worth noting that to make AI algorithms detect defects in specific types of products effectively, one needs to train them on data gathered for every specific case. Generally, it’s a complex project with some inherent risks. Deep AI expertise can help mitigate risks and uncertainties, making investments safer.

4. AI-powered Cobots to Improve Production Process

Benefits:

- Free human workers from routine, dirty, or dangerous jobs

- Eliminate errors

- Reduce variability

- Cut manufacturing costs

- Provide better visibility into assembly-line processes thanks to robot-generated data

Programmable robots of older generations were limited by the tasks they’d been designed for, and it was almost impossible to repurpose them, making robotics dependent on human supervision and expensive.

AI makes industrial robots smarter and more independent. BMW uses AI-powered robots to weld studs onto the frame of every SUV. The intelligent system detects if the studs are misplaced and fixes the issue with the help of a robot. No human intervention is needed. According to BMW Group Manager Curtis Tingle, this optimization let the company save more than $1 million a year and achieve a five-fold increase in assembly speed.

Yet, such robots are still hard to train with human-like reasoning. To compare, a child needs to see an animal to learn what it is. An ML algorithm needs 1,2 million images to do the same.

The aim of AI-powered robotics for the 4.0 industry, is to make reprogrammable robots that are capable of human-like reasoning and perfect for niche tasks, where the volume of repetitions is measured in hundreds rather than hundreds of thousands. This will pave the way for industrial robotics for small and medium businesses.

To make this happen, we need AI algorithms that generalize from smaller data, similar to what humans can do.

Companies like Vicarious are working on AI algorithms capable of top-down reasoning. This will make robots fast to train and adjust for numerous purposes.

In manufacturing, such smart robots, also called cobots, are also equipped with visual sensors to interchange tasks with humans, where complete automation is impossible. The next step in the process is teaching robots to understand human commands from voice and gestures.

5. Generative Design with Gen AI

Benefits:

- Accelerating product time-to-market

- Lower costs and emissions,

- Faster idea-validation

- User-friendly designs

- Possibility to decode proprietary technologies

- Eliminating routines like documentation creation

The success of generative design in manufacturing comes from the abundance of ready-to-use analytical data, which makes it easier for machines to train.

In manufacturing, generative design mimics human approaches to design: engineers enter the design parameters like materials, dimensions, expected functionality, and the desired costs, and the system generates as many variants as possible.

This way, Autodesk has helped Airbus to develop the Airbus Concept Plane, a jet idea of 2050. The main challenge for AI was to find ways to build a plane that is much lighter yet safer for use. Airbus also reduced the speed of engineering. A task that would take 1 minute with older software is performed in 30 milliseconds with the help of AI.

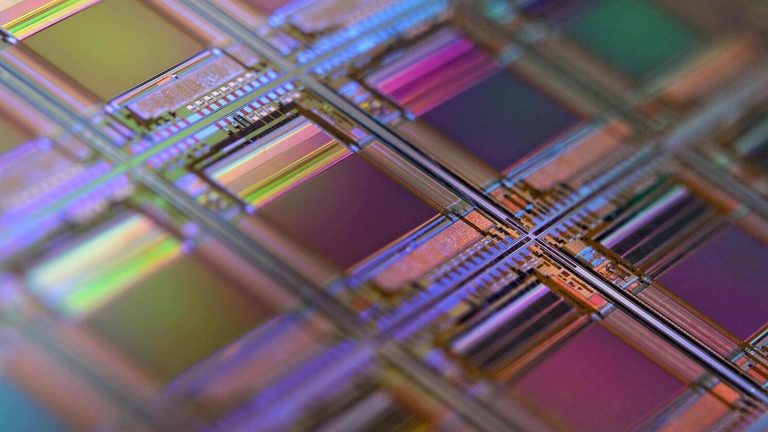

Nvidia uses AI to improve chip designs. The company has tried a combination of various AI techniques to better place big groups of transistors.

Besides discovering innovative design ideas, AI boosts the productivity of engineers as well. McKinsey reports that an undisclosed German tier-one automotive supplier gained 70% productivity by using AI to generate test vectors. Also, while using AI to translate stakeholder requests into doable drafts, the same company achieved 30% productivity gain for engineers.

6. Digital Twins to Enhance Decision-Making

Benefits:

- Enhanced decision-making

- More agile and resilient operations

- Faster time-to-market

- Rapid iterations and optimizations

- Improvements in product quality

- Waste reduction

- Better cost-to-speed balance

Industries have been using digital twins to model product performance or test and improve production or supply chains for a while. To build a digital twin, one needs data collected from all facets of organizational operations and modeling this data to mimic physical reality.

Due to the high costs of digital twins, the technology is mostly constrained to high-investment industries like aerospace, automotive, or semiconductor production.

For example, Hyundai connects robots to the metaverse to enhance manufacturing robots and gain better control over them using remote teleoperation. Similarly, Toyota partnered with Microsoft Cloud for the same reason. Mercedes Benz uses digital twins of customers to simulate test drives. According to McKinsey, this technology drives 10% revenue increases.

For now, building virtual twins is a complex and costly process, yet, the breakthroughs in generative AI make promises to make digital twins more available to SMBs. McKinsey assumes that we are at the edge of new technology: a generalized digital-twin LLM solution working as a foundation model for building digital twins across industries.

In addition, digital twin technology does not necessarily have to replicate the whole production process; it can be just one part of the process used for training or trying innovations. For example, you can create a digital twin of a single machine to monitor its performance metrics like speed, temperature, and vibration over time. You can also create a digital twin of a work environment for training purposes.

7. Intelligent Document Processing with NLP

Benefits:

- Improved data quality & usability

- Access to historical data for decision-making

- Streamlined workflows

- Enhanced compliance

- Reduced errors

- Reduced number of manual, repetitive tasks

Intelligent document processing (IDP) is an AI-powered technology that mines, reads, scans, and categorizes data from documents stored in different formats. By automating and streamlining document management, manufacturers can focus on innovation and quality, ultimately leading to better products and increased customer satisfaction.

There are several technologies behind intelligent document processing:

- Optical character recognition (OCR) is used to scan paper documents and recognize the layout and characters to transfer them into a digital format. Implemented properly, OCR algorithms can even read complex documents, such as blueprints and engineering drawings.

- Using Natural Language Processing (NLP) and language generation models like GPT allows for the analysis of extracted information. This can include text classification, data validation, entity recognition, text quality improvement, etc.

Automating document processing in manufacturing reduces the time spent on manual data entry, ensures more accurate reporting, and supports data-driven decision-making. Such a solution can significantly increase the efficiency of the management part of the production process.

Challenges and Best Practices for Implementing AI in Manufacturing

Implementing AI in manufacturing is a risk-profit balance game where being aware of risks and challenges increases your chances of success. So, let’s consider the main challenges for AI app development in manufacturing:

1. Difficult integrations

The manufacturing business often operates on a mix of old and new technologies. Sometimes, decades-old equipment is not easy to integrate into modern robotics, IoT devices, smart sensors, etc.

In some cases, legacy system modernization will require upskilling factory equipment as a part of an AI implementation project.

2. Data challenges

Effective solutions, especially those in the domain of defect detection, often require large amounts of high-quality data. Collecting, storing, and analyzing data within outdated systems or a lack of integrated data management strategies can be a serious challenge.

An effective data strategy, developed in collaboration with a data management specialist, will help solve this issue.

3. Operational risks

Implementing AI often involves making changes to critical manufacturing operations, so the process of updates must be well-planned to avoid costly mistakes. Creating robust strategies for testing, monitoring, and training can help you harness the power of AI while minimizing the risk of disruptions.

Rely on MobiDev’s Expertise to Be Part of the Future of AI in Manufacturing

While dealing with the challenges of AI implementation, as well as seeking the best ways to profit from its benefits, you may rely on MobiDev’s experience and expertise in manufacturing software development services. We’ve been operating in the software industry for over 15 years, and have completed numerous successful AI projects since 2018. Our in-house AI lab has rich experience in developing complex solutions, tailored to specific business needs.

Whether you are looking for a strategy to implement AI in your manufacturing business or need experienced engineers to bring to life your vision, we can meet you at any stage of your journey with MobiDev’s AI consulting and engineering services. Feel free to contact us to discuss your needs.